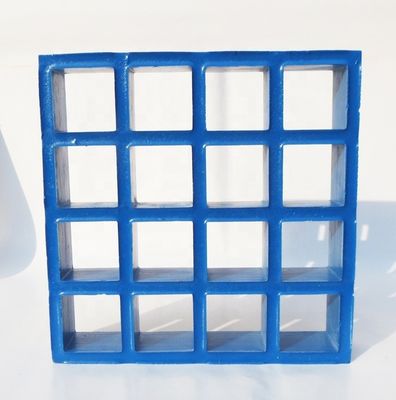

Corrosion Resistant FRP Car Washing Grating Molded Technique and Cutting Service

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | FRP molded grating |

| Model Number: | car wash grating |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 kilograms |

|---|---|

| Price: | $2.50/kilograms >=1000 kilograms |

|

Detail Information |

|||

| Application: | Carwash Grating | Surface Treatment: | Anti-slip |

|---|---|---|---|

| Technique: | Molded | Processing Service: | Cutting |

| Material: | FRP | Open Area: | 40% 80% |

Product Description

Products Description

The use of fiberglass reinforced plastic (FRP) grating in car wash facilities is attributed to several reasons:

1. Corrosion Resistance: Fiberglass, also known as glass-reinforced plastic, exhibits excellent corrosion resistance. It can withstand exposure to water and cleaning chemicals, making it suitable for the wet environment of car wash facilities.

2. Load-Bearing Capacity: FRP grating possesses strength and load-bearing capabilities, allowing it to withstand the weight and pressure generated when vehicles enter the car wash area. It maintains structural stability without deformation or damage.

3. Chemical Resistance: Fiberglass materials demonstrate resistance to various chemicals, including the cleaning agents and chemicals used in the car washing process. This contributes to preserving the surface quality and structural integrity of the grating.

4. Lightweight: Fiberglass is a lightweight material, facilitating easier installation and handling compared to heavier alternatives. This characteristic is advantageous, particularly in applications where ease of handling is important.

5. Slip Resistance: The surface of FRP grating can be designed to provide slip resistance, promoting safety in areas where water or soap may be present, such as in car wash bays.

6. Low Maintenance Costs: FRP grating typically requires minimal maintenance. It is easy to clean and does not necessitate painting or additional coatings to protect against corrosion.

7. Customization: FRP grating can be manufactured in various sizes, shapes, and colors, allowing for customization to meet specific design and aesthetic requirements.

In summary, the widespread use of FRP grating in car wash facilities is due to its multiple advantages, addressing the specific needs of the car wash environment.

1. Corrosion Resistance: Fiberglass, also known as glass-reinforced plastic, exhibits excellent corrosion resistance. It can withstand exposure to water and cleaning chemicals, making it suitable for the wet environment of car wash facilities.

2. Load-Bearing Capacity: FRP grating possesses strength and load-bearing capabilities, allowing it to withstand the weight and pressure generated when vehicles enter the car wash area. It maintains structural stability without deformation or damage.

3. Chemical Resistance: Fiberglass materials demonstrate resistance to various chemicals, including the cleaning agents and chemicals used in the car washing process. This contributes to preserving the surface quality and structural integrity of the grating.

4. Lightweight: Fiberglass is a lightweight material, facilitating easier installation and handling compared to heavier alternatives. This characteristic is advantageous, particularly in applications where ease of handling is important.

5. Slip Resistance: The surface of FRP grating can be designed to provide slip resistance, promoting safety in areas where water or soap may be present, such as in car wash bays.

6. Low Maintenance Costs: FRP grating typically requires minimal maintenance. It is easy to clean and does not necessitate painting or additional coatings to protect against corrosion.

7. Customization: FRP grating can be manufactured in various sizes, shapes, and colors, allowing for customization to meet specific design and aesthetic requirements.

In summary, the widespread use of FRP grating in car wash facilities is due to its multiple advantages, addressing the specific needs of the car wash environment.

Customizable Performance:

The properties of GRP molded grating can be customized according to specific application requirements, including different sizes, colors, and mesh patterns.

Simple instruction of FRP molded grating 1. GRP molded grating is primarily composed of glass fibers and polymer resin. This combination provides superior physical and chemical properties to the grating.

2. Manufacturing Process: The common method for producing GRP molded grating is through the molding process. In this process, a mixture of glass fibers and resin is heated and pressed into a mold, forming a sturdy grating structure.

2. Manufacturing Process: The common method for producing GRP molded grating is through the molding process. In this process, a mixture of glass fibers and resin is heated and pressed into a mold, forming a sturdy grating structure.

Glass Fiber Reinforced Plastic (GRP) molded grating is a structural material made through the molding process using glass fiber reinforcement polymer (FRP).

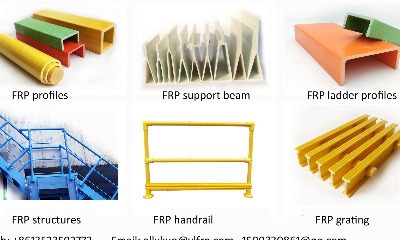

FRP molded grating type: FRP molded grating Applications: GRP molded grating finds widespread applications in various fields, including but not limited to:

* Industrial platforms and walkways

* Chemical plants and refineries

* Wastewater treatment facilities

* Marine and offshore platforms

* Power plants and substations

* Food processing and beverage plants

* Industrial platforms and walkways

* Chemical plants and refineries

* Wastewater treatment facilities

* Marine and offshore platforms

* Power plants and substations

* Food processing and beverage plants

Packing And Shipping

Packing type: pallets, wood carton, etc. also could packing according to customer's requirement.

Shipping: land shipping, air shipping, railway shipping, express delivery(length can't over 2.5m)

Company Profile

Who are we?

Due to environmental policies, Zhengzhou Yalong Putex Composite Materials Co., Ltd. that established in 1994 relocated to Xihua County, Zhoukou in 2022. Subsequently, affected by local tax policies, the company registered a new legal entity, Henan Hongji Composite Materials Co.,Ltd. Starting from 2023, the company gradually conducted its business under the name of the new legal entity. Simultaneously, thecompany introduced new production equipment to enhance production capabilities and better serve customers.

What do we do?

Henan Hongji Composite Materials Co, Ltd located in Zhoukou city, Henan province, have 6 FRP pultrusion lines, specialized in manufacturing frp pultrusion profiles, FRP grating, handrail/fence/guardrail, ladder profiles, industrial window, shutters, various customized FRP product. We start export business since 2007, already exported to America, Europe, Africa, middle east, southeast Asia, Australia, etc.,over 30 countries. Henan Hongji offer stable product quality, rich experience in production and R&D, and timely after-sales service. We can customize production according to customer requirements and put customer

satisfaction first, welcome contact us.

Henan Hongji Composite Materials Co, Ltd located in Zhoukou city, Henan province, have 6 FRP pultrusion lines, specialized in manufacturing frp pultrusion profiles, FRP grating, handrail/fence/guardrail, ladder profiles, industrial window, shutters, various customized FRP product. We start export business since 2007, already exported to America, Europe, Africa, middle east, southeast Asia, Australia, etc.,over 30 countries. Henan Hongji offer stable product quality, rich experience in production and R&D, and timely after-sales service. We can customize production according to customer requirements and put customer

satisfaction first, welcome contact us.

FRP pultrusion workshop

Raw materials

Where are we?

Facotry address:

No. 166, Huacheng Road, Economic Development Zone, Xihua, Zhoukou, Henan province, China

Zhengzhou Office Address:

No.3 Xuesong Road, High and New Technology Industries Zone of Zhengzhou, 45001,China

Why Choose Us?

1. Factory direct sell, offer competitive price, customized product

2. We choose good quality raw materials to ensure product quality

3. Free samples are available

4. We offer 2 years goods warranty

5. 30 years of fiberglass pultrusion production and application experience

Facotry address:

No. 166, Huacheng Road, Economic Development Zone, Xihua, Zhoukou, Henan province, China

Zhengzhou Office Address:

No.3 Xuesong Road, High and New Technology Industries Zone of Zhengzhou, 45001,China

Why Choose Us?

1. Factory direct sell, offer competitive price, customized product

2. We choose good quality raw materials to ensure product quality

3. Free samples are available

4. We offer 2 years goods warranty

5. 30 years of fiberglass pultrusion production and application experience

Customer Photos

We have been engaged in export trade since 2005, supplying our products to over 30 countries across North America, Central and South America, Europe, Australia, Southeast Asia, Africa, and more. Our products are known for stable quality, competitive pricing, welcome worldwide customer contact.

Contact Us

Contact: Ally Kuo

Mobilephone/whatsapp/wechat: +8613523592773

Tel:+86-371-67981056

Email: allykuo@ylfrp.com

Email: allykuo@ylfrp.com

website: http://www.ylfrp.com

Wechat

Whatsapp

Want to Know more details about this product